Packaging machines for the dairy industry

-Made in Germany |

|

|

Finnah Packtec GmbH provides customers in the international dairy industry with high-performance packaging machines for every application.

For more than 40 years, Finnah Packtec has designed and built high-performance packaging machines at its site in Ahaus. The many years of experience gained through the ever-new impulses of the customers flow into every new machine generation. The emphasis is always on customer requirements and gentle product treatment.

Today, the consistent use of single servo drives in conjunction with intelligent automation technology and precision mechanical sequences and movements guarantee the high performance of every Finnah packaging machine.

Special requirements for cup or bottle decoration and shapes as well as special dosing patterns are developed and implemented in close cooperation with the customer.

Feasibility studies and tests are carried out withthe customer if required in our own pilot plant station.

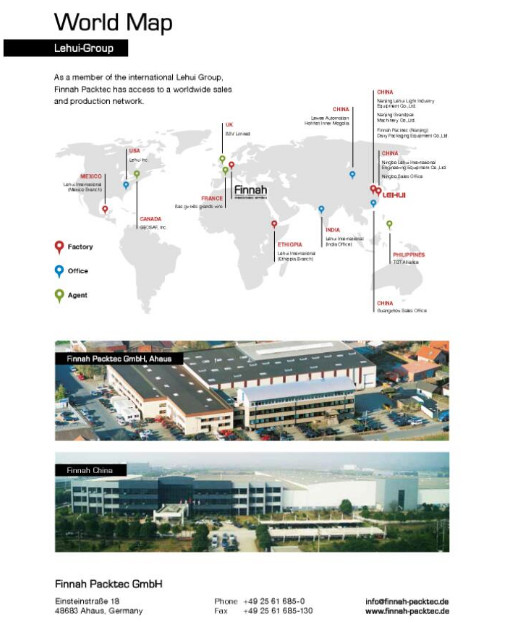

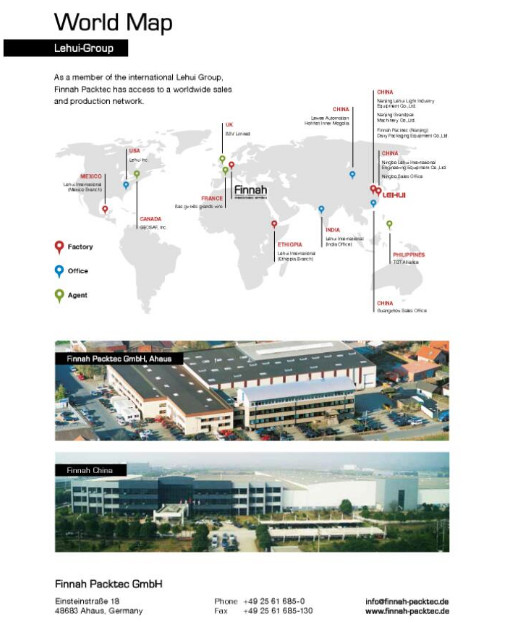

With the Chinese listed company LEHUI International, Finnah Packtec has a strong parent

company with a worldwide network of sales and production sites. In this group Finnah Packtec stands for “Made in Germany” and thus for engineering at the highest level. We gladly accept this role, because we see ourselves as partner of our customers and accompany every customer from the first idea throughout the whole project phase up to the acceptance and beyond. |

|

|

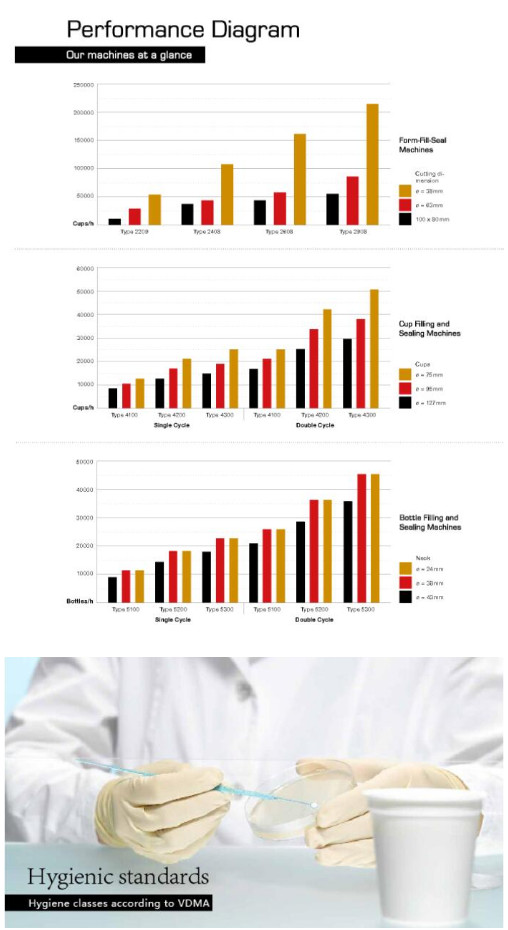

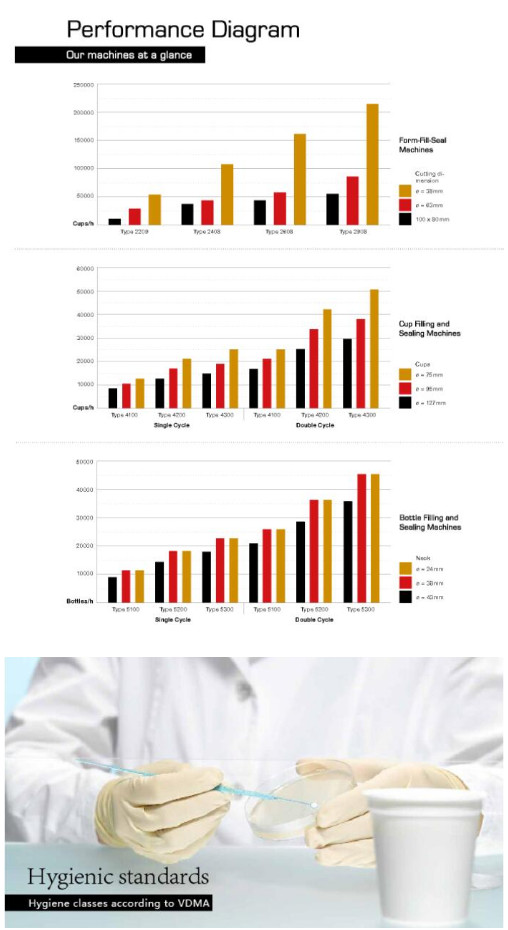

The four standard types of FFS machines proposed by Finnah cover an output range of up to 200,000 cups per hour. The machines can handle all currently available cup and lid films without any problems and can optionally be retrofitted by machine-integrated decoration systems.

The form-fill-seal machine combines years of experience with future-oriented engineering at a high performance level:

|

|

· Variability thanks to a modular structure.

·Latest servo-technology supports the flexibility.

·Optional, integrable decoration systems enhance the appearance of the cup and thus

support the attractiveness of the product at the POS.

·Various hygiene concepts up to full aseptic systems.

·Sophisticated cleaning and sterilisation systems to increase the effective production time. |

|

Finnah offers three types of space saving, linear cup filling and sealing machines, the difference being in the width of the machine. This makes it possible, depending on the dimension of the cups, to cover an output range up to 58,000 cups per hour. The choice of cup and lid material is completely free; also snap-on lids – filled or not – can be processed easily. Cups with identical diameters but otherwise different shapes can be handled without any format changes being necessary; simply by adjustments in the machine program.

The cup filler is particularly oriented to the customer needs and allows a future-oriented,

flexible application:

|

|

· The modular system enables cost-optimised and largely individual and needs-based machine design.

·Sophisticated drive concept for greater ease of maintenance and user-friendliness.

·Ergonomic machine design for mutual machine access.

·The positive cup destacking increases the flexibility with regard to the different cup shapes to be processed.

·Sophisticated cleaning and sterilisation systems to increase the effective production time. |

|

Finnah offers three standard types of bottle filling and sealing machines for common plastic bottles,the difference being in the width of the machine. This makes it possible, depending on the dimension of the bottle, to cover an output range up to 46,000 cps per hour. Another machine type permits the combined filling of glass and plastic bottles.

The bottle filler is the logical technical development of the cup filler – tried and tested know-how has been improved upon:

|

|

· Modular system

· Drive concept

· Ergonomic construction

· Ease of use and maintenance

· Fully aseptic, optimal sterilisation and cleaning times |

|

Depending on the defined product characteristics as well as the selected distribution channel and the desired minimum shelf life, the „correct“ clean room technology of the machine is determined and thus a hygiene class. The hygiene classes applied by us comply with those defined by the VDMA (German Engineering Federation) and have

to meet defined demands on machine and process technology.

Traditionally, Finnah uses H2O2 for the inline-sterilisation of all packaging materials and thus achieves the safe aseptic filling of even sensitive products. Continuous and practice-oriented system improvements result in the fact that in FFS machines as well as in cup and bottle fillers a kill rate of log 5 is achieved which is proven by independent institutes

on a regular basis.

All types of free-flowing and highly viscous products, also with particles like fruit pieces or pulp in fruit juices, can be filled gently and specifically; hot or cold filling is neither a problem. On a simple touch of a button, the patented servo-driven filling system allows unique and reproducible filling patterns and variations. Furthermore, special dosing

nozzles are available for different dosing applications, which are specially selected depending on the product and dosing pattern.

The simultaneous filling of different flavours or the dosing of different layers in one cup as well as a cream topping belong to the standard repertoire. Finnah dosing systems are CIP and SIP capable and low maintenance by design.

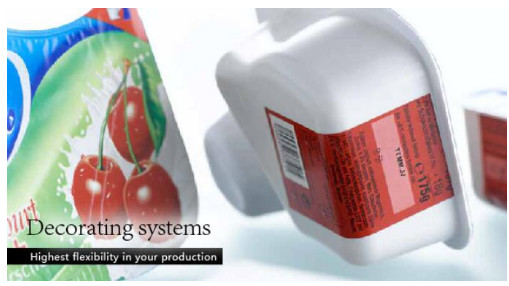

Finnah’s powerful decoration systems are designed as retrofittable, integrated machine components. On the one hand, there are various in-mould decoration systems that can only be used in form, fill and seal machines:

|

|

· Banderole labels from a role whereas also conically shaped cups can be labelled

· Side labels from a magazine or role

· Bottom labels from a magazine or role

· L-shaped labels from a role |

|

0574-65836556

0574-65836556

skype

skype