Lehui’s Laser Welding Technology Boosting Chinese Lunar Landing Program

- Categories:Corporation News

- Author:

- Origin:

- Time of issue:2016-09-18

- Views:0

(Summary description)

Lehui’s Laser Welding Technology Boosting Chinese Lunar Landing Program

(Summary description)

- Categories:Corporation News

- Author:

- Origin:

- Time of issue:2016-09-18

- Views:0

Since 2008, Lehui has been involved with the Chinese Space Satellite and Lunar Probe Project, providing stainless steel laser-welded dimple jackets for the test cabin of the environment simulators. Lehui has always taken much pride and feels very honored to have been part of this program and to contribute to the development of China's aerospace technologies.

Lehui – Always imitated but never bettered

Lehui has been recognized in China as the pioneer company that developed and manufactured laser welded jackets, and as such holds a number of patents for the technology. In China, Lehui's fermenters with laser welded jackets have been regarded as part of the National New Products Program, and as such Lehui has been an integral part of the group who has drafted and compiled the industry standard for laser welded jackets.

Our History

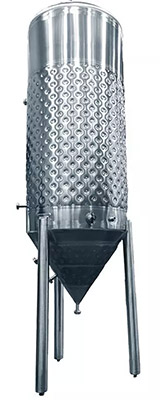

In 2003, Lehui has manufactured the first beer fermenter with laser welding stainless steel jacket in China, which has been the largest fermenter so far in China with effective volume of 600 m³ and put into use in the Tsingtao Brewery (second plant).Since then, Lehui has supplied over 2000 fermenter with ammonia cooling for China's brewery industry, helping breweries saving ten of million annually.

Why Laser Welded

Using laser welding technology, the dimple jacket fermenter can work at pressures up to 90bar, meeting the highest standards for security when using direct ammonia cooling. Compared with traditional cooling methodologies, cooling with ammonia can save significant amounts of energy, with estimated savings of around 24%

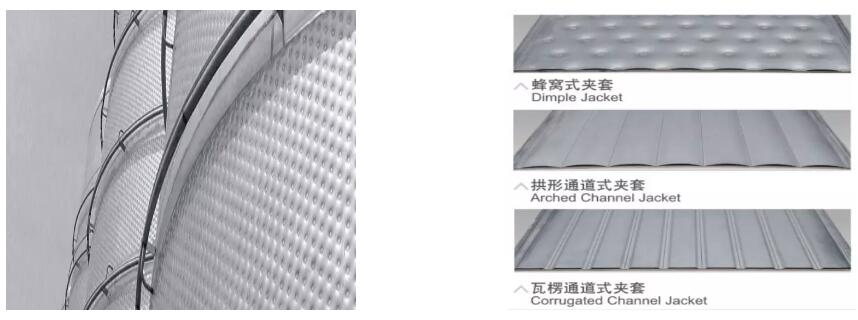

Different Types of Laser Welded Jackets

- Dimple jacket: for ammonia direct cooling;

- Corrugated channel jacket: for glycol water jacket;

- Arc channel jacket: for glycol water jacket;

- Heat-exchange plate: for evaporation condensation, ice preparation and heating.

Our customers: (Part)

Lehui's Patented Technology

- Built-in laser-welded heat transferring jacket (utility model)

- Arched channel jacket (utility model)

- Heat transfer jacket with new structure (patent for invention)

- Jacket tank (patent for invention)

- Jacket unit, jacket tank & Manufacturing method of jacket tank (patent for invention)

- Jacket & jacket tank (patent for invention)

- Jacket unit and jacket tank (utility model)

- Dimple jacket fermentation tank (patent for invention)

Lehui's Patented Technology

- LHPFJ laser welding dimple jacket taper fermenter, national key new product certificate

- LHPFJ laser welding jacket taper fermenter, outstanding new industrial product of Ningbo city (Ningbo municipal government)

- Development and application of laser welding jacket taper fermenter, the first prize of scientific and technological progress of CADA (China Alcoholic Drinks Association)

Applications of Laser Welded Jackets in Brewing Process

The patented internal jackets developed by Lehui give great advantages in heating of the mash tun, when compared with external jackets. The internal jackets have a higher heating efficiency than the external jackets, and improve the heating rate significantly. With the dimple surface design within the vessel, turbulent flow of the liquid is created, improving the heating efficiency and reducing the fouling, extended the time interval between CIPs.

Dual-thin Plate Fermenters

The Laser welding of the base plates and the jackets, combines both plates thoroughly to make a single enclosed construction. As high pressure water is put into this space, so the dimples are created by the plate deformation and bulging on both sides. The finished plate resembles a concave-convex looking dimple, and gives the following advantages:

• The process reduces the material required for manufacture by 20-30%.

• The heating parameter is higher than that of traditional jackets, for K value is doubled at least.

• Laser welding has been applied for jackets, and the welding quality is steady and reliable with high production efficiency.

• Last but not least, because of using 2B plates, there is no need for polishing, which reduces manufacturing cost.

Other industry applications

The laser welding heat exchange plate can be expanded to some other industries, like biochemistry, food, fine chemical engineering, electron, medicine, environment protection, daily use chemical, chemical products and daily necessities, etc.

lehuiwx

Follow《LEHUI》official accounts on WeChat: lehuiwx

Contact us:weixin@lehui.com

Official website:www.lehui.com

Scan the QR code to read on your phone

Recommended news

See you in BrauBeviale 2019

- Process equipment: 0574-65836556

- Packaging equipment: 025-52733601

- Fax : 0574-65836111

- E-mail : info@lehui.com

-

Address :

Xiangxi Electromechanical Industrial Park,

Xiangshan County,Ningbo City, Zhejiang Province, China

CONTACT US

- SITE NAVIGATION

- HOME

- ABOUT US

- PRODUCTS

- SERVICES

- NEWS

- RECRUITMENT

- CONTACT US

Copyright @2017 LEHUI First for value 浙ICP备2020031996号 Powered By www.300.cn SEO

0574-65836556

0574-65836556

skype

skype